THIS INTERNATIONAL ON DEMAND SUMMIT IS AN INDUSTRY… More

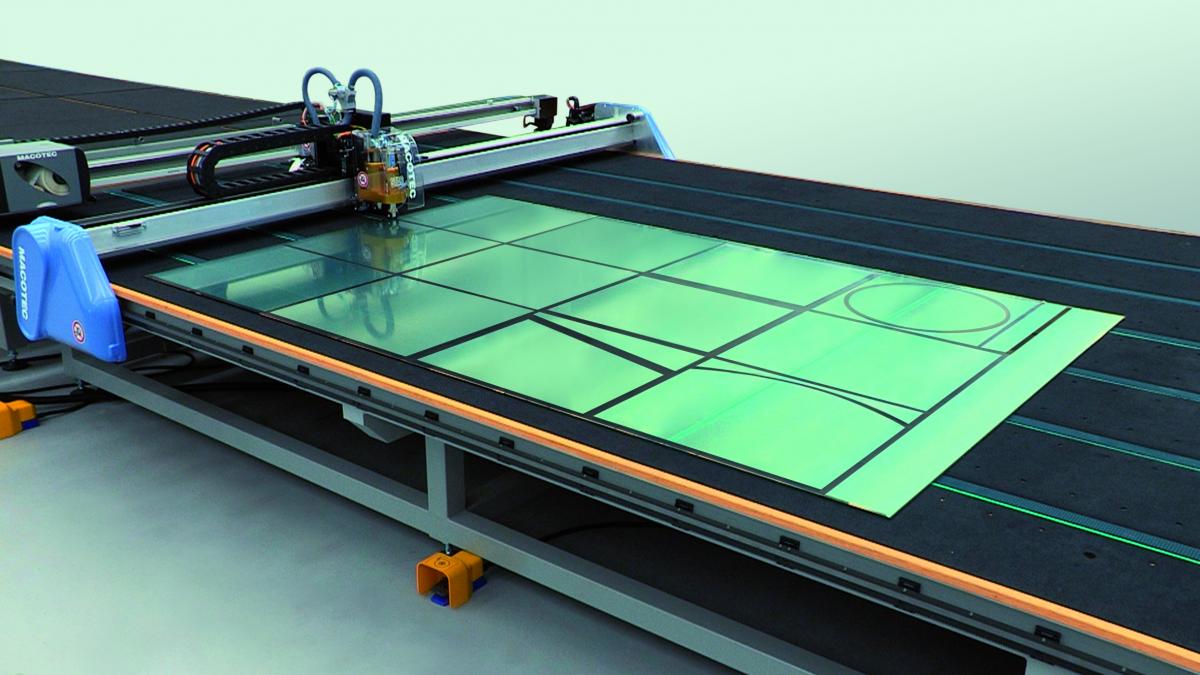

Macotec: Flat Glass Technology That Boosts Productivity

Leading the industry for over 20 years, Macotec designs and builds the most productive and technologically advanced systems for glass cutting, handling and storage.

Leading the industry for over 20 years, Macotec designs and builds the most productive and technologically advanced systems for glass cutting, handling and storage.Among Macotec’s technological wonders are its advanced cutting systems, which are extremely versatile machines. They are designed for cutting both monolithic and laminated glass and they range from completely automated handling and cutting lines to simple stand-alone cutting tables. The new, patented System to remove the Protective Film (TPF ) on coated surfaces is another ground breaking innovation by Macotec.

TPF is normally used to protect the glass surfaces from mechanical damages often incurred during the fabrication process. In addition, TPF enhances the product’s environmental stability.

Macotec’s TPF technology for protective film and Low‐E soft coating removal is equipped with a powerful Suction system which is positioned outside of the machine. A dedicated “head” allows for management of the removal process with greater speed and efficiency and most importantly, with maximum protection of the glass surface. The removal process eliminates all plastic residues and the system also allows for labelling of the glass surface resulting in easier identification. Film removal can be performed in various modes:

- X – Y cut

- Diagonal straight cut

- Shaped cut

- With standard width (10 + 10) or higher (multiple runs)

Related Articles:

Recent News

POSTED ON