Italian Plastic Machinery State of the Industry Report 2015: Sprinting Forwards for the First SIx Months

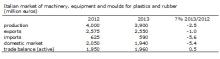

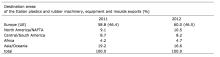

The statistical analysis performed by Assocomaplast (Italian trade association, part of CONFINDUSTRIA, representing over 160 companies) on foreign trade data provided by ISTAT regarding the first six months of this year , reveals – in comparison to January-June 2014 – a markedly positive performance for Italy's exports and imports of plastics and rubber machinery, equipment and moulds. The growth recorded since the first months of 2014 has continued this year and actually has increased: by the end of June 2015, the rise in purchases from abroad approached 17%. This provides further reassurance